Acoustic analysis of ballistic protective plates

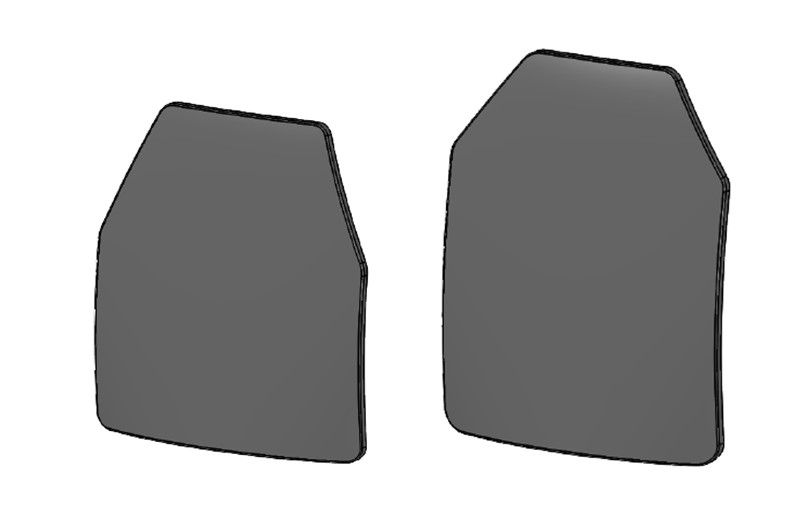

Ballistic protective plates constitute an important element for the personal security of the Swiss Armed Forces. These are ceramic plates for the highest protection classes, which can experience a reduction in the intrinsic protective effect due to external influences, in addition to the actual ballistic impact, such as handling. Just dropping a plate can lead to fractures which considerably reduce ballistic protection, even if the defect is invisible to the naked eye. To ensure the safety of members of the Armed Forces, it is important to have a test procedure with which the condition of the protective plates can be assessed reliably and quickly.

The condition of ceramic protective plates is usually assessed using x-ray images: damage to the plate, such as cracks, appear in high contrast on the x-ray, while they often remain invisible during inspection with the naked eye. And depending on the alignment, position and size, a break can be difficult to recognise on an x-ray image. For these reasons, an alternative method of inspection is required. Based on a project within the policy research, an innovative procedure has been developed at armasuisse S+T to check the quality of protective plates. Together with the School of Engineering Haute Ecole Arc in Le Locle, armasuisse S+T examined an acoustic procedure which aims to simplify and accelerate the process of testing ceramic protective plates. The principle is based on making the plate vibrate. The vibrations induced are related to the inner forces in the plate. Defects such as cracks can change these, which can be detected acoustically. Analysis of the acoustic signals thus allows defective protective plates to be rapidly identified, as in most cases these change the acoustic signature of a protective plate. However, the sensitivity of the method should be examined more closely. After a demonstrator had been developed as part of a research assignment, the aim was to examine the suitability in the operative environment of the customer. In this context, further demonstrators were procured and conceded to the AFLO for test purposes as part of a «test run».

Based on the collected findings, utilisation has now been initiated in the form of a procurement project. It is the first innovation project that has now been transformed into a procurement.